Electrostatic Discharge (ESD) is a phenomenon that can cause severe damage to electronic components. ESD occurs when a static electrical charge moves from one object to another, often from the human body or work tools to sensitive electronic components. When this electrostatic flow touches a component, an energy surge can damage its internal structure, even at relatively low voltages, such as 30V.

Antistatic wrist straps are essential when working inside a computer case. This tool conducts static electrical charges from the body to the computer chassis, thus preventing damage due to ESD. By wearing an antistatic wrist strap, users can work more safely and reduce the risk of damage to sensitive electronic components.

The main function of the antistatic wrist strap is to prevent damage to components due to ESD. By ensuring that electrical charges do not accumulate in the body, this tool helps to maintain the integrity of electronic devices during the repair or maintenance process.

Antistatic Wrist Strap Care Steps

1. Initial Examination

Before putting on the antistatic wrist strap, do a preliminary check to make sure the tool is in good condition and safe. Some things to check are:

- Worn or Broken Straps

Make sure the wrist strap strap is not damaged, such as wear, cracks, or breakage that could affect its function.

- Loose Grounding Joints

Check that the connection between the grounding lead and the wrist strap is properly secured. Loose connections can cause the flow of static electricity to be uncontrolled.

- Dirt or Oil Buildup

Check for dirt, oil, or dust in: Wrist strap contact points, Ground lead connections, and Hook clips on the computer chassis. Dirt can interfere with the flow of electricity, so the wrist strap does not work properly.

Dirt can block the flow of electricity, so the wrist strap does not function properly.

2. Cleaning the Wrist Strap

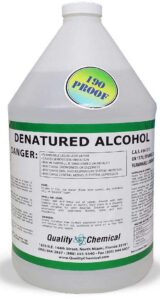

In order for the antistatic wrist strap to remain in good condition, it is important to clean it regularly. Denatured alcohol can be used to remove dirt or oil that has adhered to it. Avoid using harsh or abrasive cleaners that could damage the straps.

Clean important areas that come into contact with electricity, such as:

- The parts that come into contact with the skin must be clean to maintain good conductivity.

- Make sure this area is clear of debris for the grounding joint to function properly.

- Clean the clips so that the connection to the computer chassis is not obstructed by dirt or corrosion.

3. Testing Continuity

After checking the physical condition and hygiene of the antistatic wrist strap, the next step is to test the continuity of the electrical line using a multimeter. This step is very important to ensure that the antistatic wrist strap is functioning properly. With a multimeter, you can measure the resistance between the contact points on the wrist and the clips connected to the computer chassis.

How to use the Multimeter

- Set the multimeter to resistance measurement mode (ohm meter).

- Connect one of the multimeter probes to the wrist contact point on the wrist strap.

- Connect the other probe to the computer chassis connection clip.

If the multimeter shows a zero ohm reading, it means that the power line is in good condition and there is no resistance.

If there is high resistance or no reading, there is a problem with the connection or power line, such as a broken wire or a dirty contact point.

4. Adjusting the Wrist Strap

Adjust the antistatic wrist strap so that it is not too tight or loose. The well-fitting strap will ensure good contact with the skin, but remain comfortable during prolonged use. Make sure the settings do not interfere with hand movements while working.

For best results, make sure that the parts that come into contact with the skin are free of obstructions. This means that there are no clothes, hair, or other objects that block the contact between the rope and the skin. This direct contact is important so that the electrostatic charge can flow properly from the body to the computer chassis, thereby reducing the risk of damage from ESD.

5. Securing the Ground Cable

Make sure the ground wire is properly connected to the antistatic wrist strap. These cables serve to carry the static charge from your body to the computer chassis, so it’s important to ensure a good connection.

After connecting the ground wire, double-check that the connection is securely attached and does not come off easily. Perform a visual inspection and pull the cable slightly to ensure a strong connection. If the connection feels loose or unstable, fix it to keep it secure during use.

6. Connecting to a Computer Chassis

The final step is to make sure the antistatic wrist strap is properly attached to the computer chassis to conduct static electricity safely.

Connect the wrist strap clip to a clean metal part of the computer chassis. Make sure the hook location is:

- Free from paint, dust, oil, or corrosion.

- It is a metal part that is directly connected to the computer’s grounding.

- Clean metal dots to ensure the smooth flow of static electricity.

- Avoid installing clips in painted areas or non-metallic parts, as this may interfere with the flow of electricity.

With a clip connected to the computer chassis, the wrist strap will conduct static electricity from the body to the chassis, where the charge will be safely channeled, protecting the electronic components from damage caused by ESD.

Understanding ESD Protection

Static electricity can damage electronic components, so it is important to conduct them safely in sensitive environments. The antistatic wrist strap helps to carry the static charge from the body to the computer chassis in the following ways:

Working Principle

The antistatic wrist strap is connected to the ground via a grounding cable. When worn, parts that touch the skin will conduct a static electric charge from the body to the ground. This process is fast, usually within 0.1 seconds, so the charge can be released before damaging the electronic components.

Direct Contact

For effective static electricity conduction, the metal buckle on the wrist strap must be in direct contact with the leather. This ensures that there are no obstructions that impede the flow of electrical charge to the ground.

Safety of Use

By using an antistatic wrist strap that is well connected to the ground, the user can prevent the build-up of static electric charges. This is especially important when working with sensitive components, such as CMOS chips and microprocessors, which can be damaged by ESD.